Cost of Corrosion

The Real Cost of Corrosion

NACE Study Estimates Global Cost of Corrosion at $2.5 trillion annually

How Much is Corrosion Costing You?

CORROSION COSTS AND PREVENTIVE STRATEGIES IN THE UNITED STATES

Report by CC Technologies Laboratories, Inc. to Federal Highway Administration (FHWA), Office of Infrastructure Research and Development, Report FHWA-RD-01-156, September 2001.

It is known that the corrosion of metallic structures has a significant impact on the U.S. economy, including infrastructure, transportation, utilities, production and manufacturing, and government. A 1975-benchmark study by Battelle-NBS calculated the cost of corrosion to be $70 billion per year, which was 4.2 percent of the nation’s gross national product (GNP). Other studies, both in the United States and abroad have addressed the cost of corrosion as well.

A need was identified to carry out a systematic study to estimate the current impact of metallic corrosion on the U.S. economy and to provide strategies to minimize the impact of corrosion. Through discussions between NACE International (The Corrosion Society), members of Congress, and the Department of Transportation (DOT), an amendment for the cost of corrosion was included in the Transportation Equity Act for the 2st Century (TEA-21), which was passed by the U.S. legislature in 1998. In the period from 1999 to 2001, CC Technologies conducted the research, in a cooperative agreement with the Federal Highway Administration (FHWA).

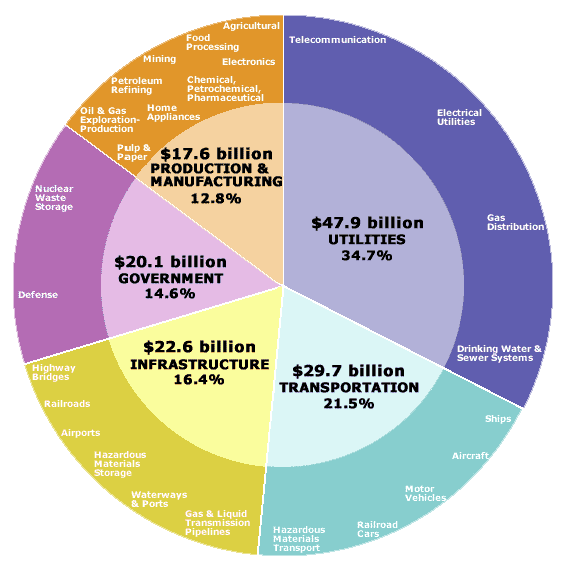

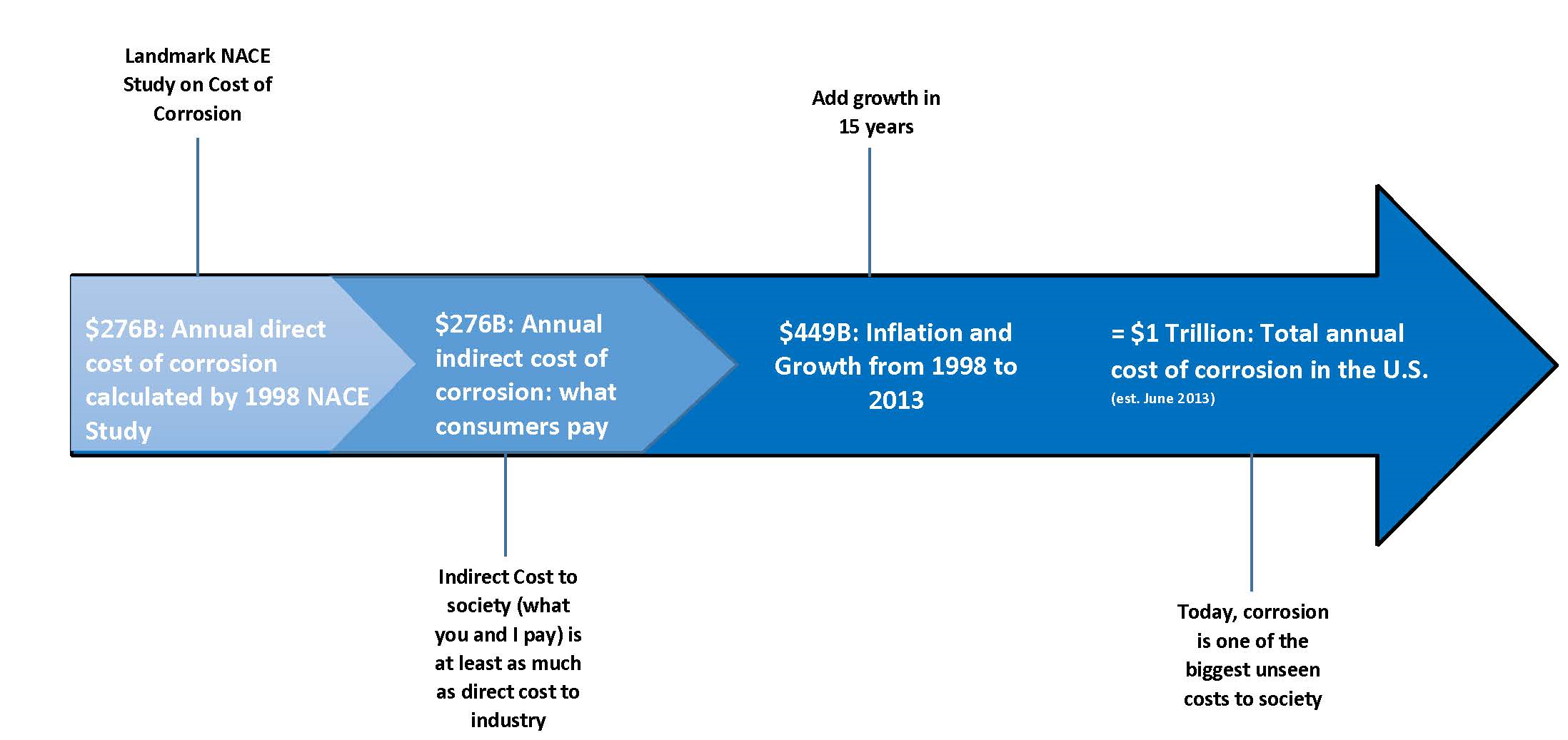

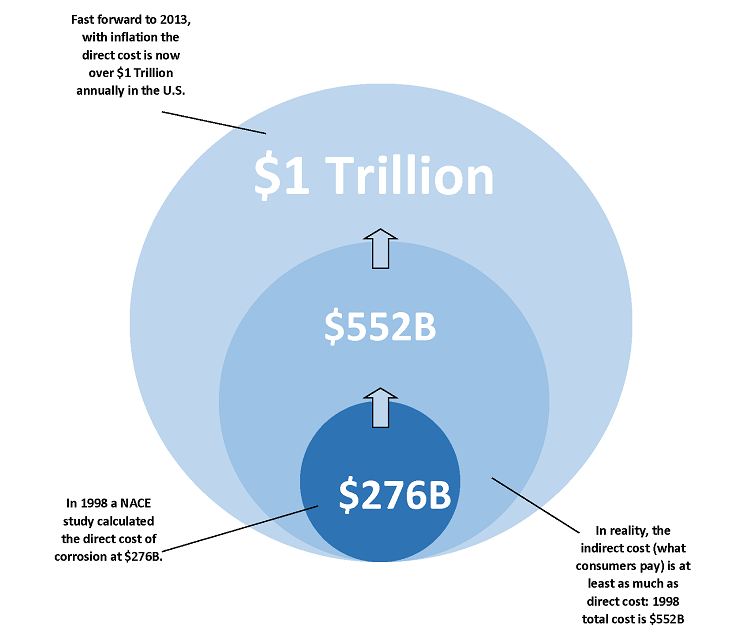

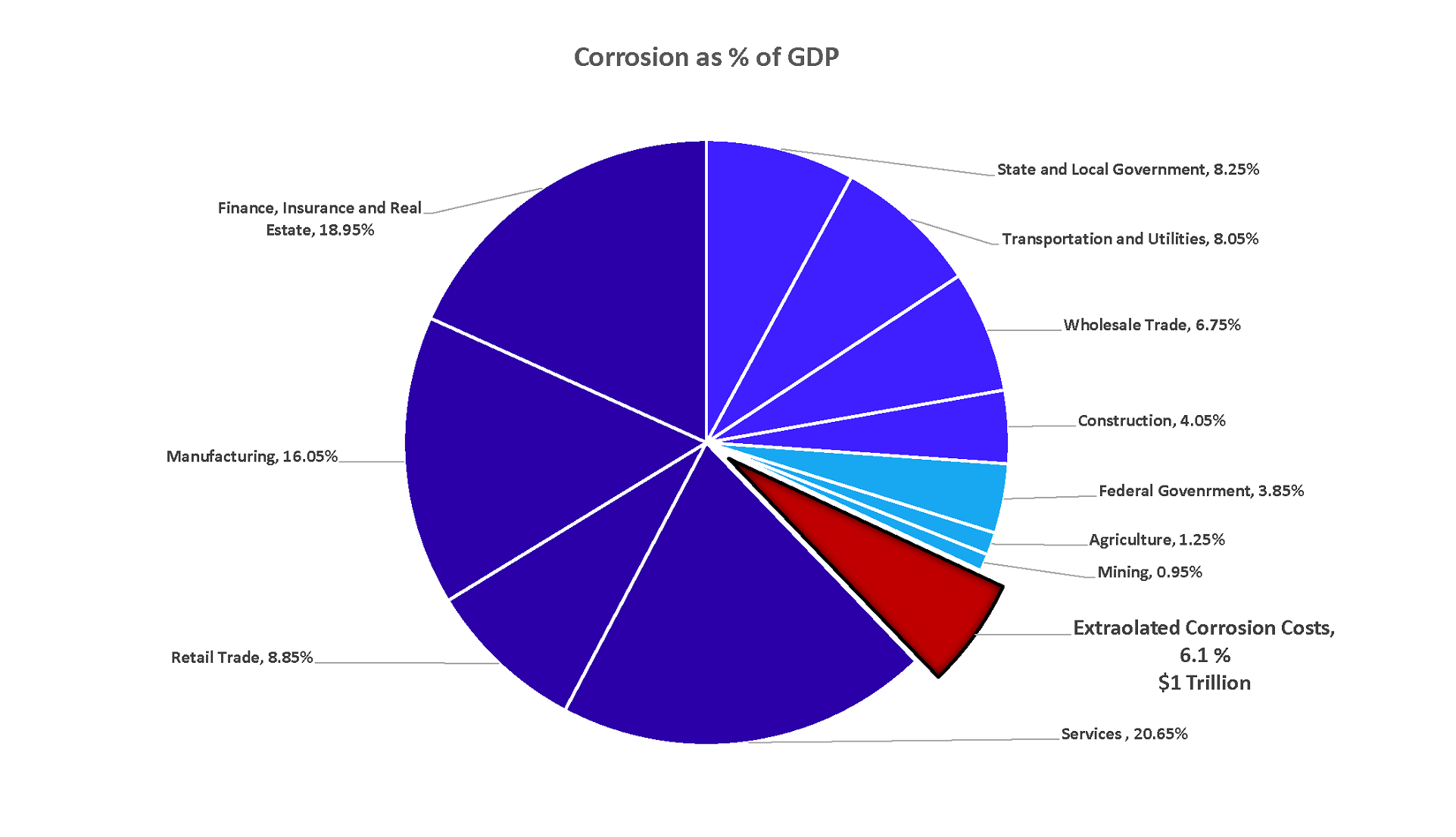

In this study, the total direct cost of corrosion was determined by analyzing 26 industrial sectors, in which corrosion is known to exist, and extrapolating the results for a nationwide estimate. The total direct cost of corrosion was determined to be $279 billion per year, which is 3.2 percent of the U.S. gross domestic product (GDP). Indirect costs to the user (society costs) are conservatively estimated to be equal to the direct costs. This means that the overall cost to society could be as much as six percent of the GDP. Often, the indirect costs are ignored because only the direct costs are paid by the owner/operator.

New technologies to prevent corrosion continue to be developed and cost based corrosion management techniques are available to further lower corrosion costs. However, cost-effective methods are not always implemented. Better corrosion management can be achieved using preventive strategies at every level of involvement (owner, operator, user, government, Federal regulators, and general public).

The preventive strategies include:

- Increase awareness of large corrosion costs and potential savings.

- Change the misconception that nothing can be done about corrosion.

- Change policies, regulations, standards, and management practices to increase corrosion savings through sound corrosion management.

- Improve education and training of staff in recognition of corrosion control.

- Advance design practices for better corrosion management.

- Advance life prediction and performance assessment methods.

- Advance corrosion technology through research, development, and implementation.

This report will be of interest to government regulators and policy makers involved in materials-related issues, the general public, and practicing engineers concerned with materials of construction and process design.

According to the Federal Highway Administration (FHWA) and NACE International (National Association of Corrosion Engineers), rust is the cancer of iron and steel and the direct cost of corrosion in the United States is $276 billion annually. No matter what it is, if it is made from metal and exposed to the elements, it will rust and corrode. Whether it is the workman’s tools, the metal box tools are stored in, highway bridges, motor vehicles, ships, railroad cars, agricultural (home and farm), metal equipment, trucks, tractors, wastewater treatment plants, ports, oil wells, cranes, etc., rust and corrosion will occur if they are left unprotected. The Independent Scientific Studies of Rust Bullet focuses on anything made of metal and the benefits of Rust Bullet’s® coating on the rust and corrosion of that metal.

Special emphasis is put on Rust Bullet’s ease of application, maintenance, repair, and long-term rust/corrosion prevention providing a substantial savings in labor and maintenance costs.

This revolutionary Patented New Technology that will allow you to receive

a maximum return on your investment dollar is now here!

The Growing Cost of Corrosion

NACE, and G2mtlabs. “The Cost of Corrosion Exceeded $1 Trillion in United States in 2013.” G2MT Laboratories. N.p., 01 June 2011. Web. 10 Apr. 2015.

NACE, and G2mtlabs. “The Cost of Corrosion Exceeded $1 Trillion in United States in 2013.” G2MT Laboratories. N.p., 01 June 2011. Web. 10 Apr. 2015.-

facebook

-

YouTube

Outside of US: 1-775-829-5606

Toll Free: 1-800-245-1600

Canada Toll Free: 1-800-789-3993

Email: Support@RustBullet.com

Monday-Friday 8:30am to 5:00pm PST

300 Brinkby Ave., Suite 200

Reno, NV 89509

USA